This article by Tim Page-Bottorff was published in

BLR’s inaugural issue of Safety Decisions, April 2015

Training should be a top priority in your safety program. Are your practices aligned with what’s actually effective in the real world?

There are more resources at a safety trainer’s disposal than ever before, from simple PowerPoint presentations to full-blown online training. But few safety professionals actually employ the type of training they believe is most useful.

Safety training by the numbers

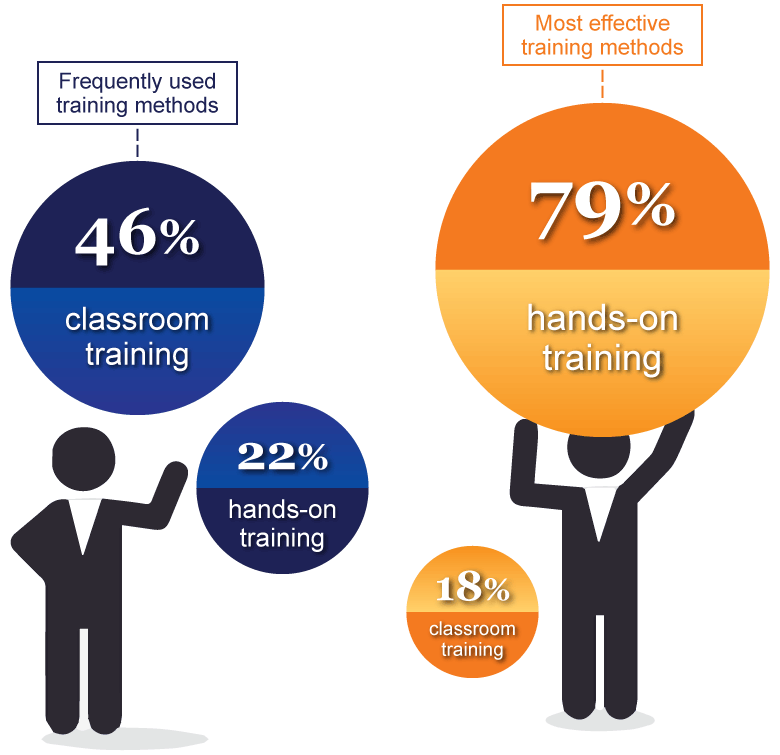

A recent survey by BLR asked individuals who are responsible for safety at their company which method they most frequently relied upon to deliver safety training. The survey results revealed that the most common type of training by far was a presentation in a classroom setting, with almost 46% of respondents regularly using traditional tools like handouts, videos, and PowerPoint.

The second-most popular method of training is a blend of classroom and selfpaced learning, which is employed by 27% of respondents. Coming in third was handson training in the field, with only 22% of those surveyed saying they most frequently provided hands-on training in the field.

But ask respondents which method they think is most effective at training workers and you get a much different response. The vast majority believed that hands-on training in the workplace was the best way to influence behavior, with over 79% of those surveyed selecting this option. Classroom training was a distant second at 18%.

Hands-on engagement

And it turns out they’re right—engaging employees in direct, hands-on training is more effective than traditional classroom safety lessons. A research paper examined 123 studies of safety training from 1971 to 2003 and concluded that “as training methods became more engaging (i.e., requiring trainees’ active participation), workers demonstrated greater knowledge acquisition, and reductions were seen in accidents, illnesses, and injuries.” The paper also noted that lecture-style training is “one of the least engaging methods of safety and health training.”

So it’s clear that hands-on training better engages employees, which can lead to stronger learning and higher retention rates, which in turn should make employees more likely to follow compliance measures.

Hands-on training better engages employees, which can lead to stronger learning and higher retention rates.

From one year to the next there is little variance in most compliance training. Rules may be amended occasionally and in rare occasions training materials are even updated, but for the most part trainers pop in the same video and cover the same steps every time. This is especially true for topics like lockout/tagout (LOTO) where few improvements can be made on wellestablished best practices.

For long-tenured workers, compliance training can get stale quickly. Once employees start to feel any aspect of safety training is redundant and their eyes glaze over every time LOTO is mentioned, their long-term risk of injury increases as a result.

For long-tenured workers, compliance training can get stale quickly. Once employees start to feel any aspect of safety training is redundant and their eyes glaze over every time LOTO is mentioned, their long-term risk of injury increases as a result.

Fortunately, there are few better ways to combat compliance-related complacency than to get in the field. By providing hands-on training you can help freshen up otherwise dull compliance training, and you’ve got a better chance at noticing (and correcting) bad habits while reinforcing good habits that experienced employees have developed over the years.

And when it comes to OSHA-mandated reviews such as periodic inspections, you’re able to kill two birds with one stone by completing your mandated report while also providing more direct and engaging LOTO training.

However, achieving a higher level of engagement requires more than taking your standard safety presentation and delivering it on the shop floor. As the research paper that was mentioned above noted, safety training is more effective when it elicits active participation.

Learning through participation

The reason active participation is so effective is because it gets employees to think through things themselves, and in doing so they begin building new habits. People naturally learn by doing, and the entire apprenticeship system in most trades is built on the belief that it requires practice in order to properly hone one’s practical skills and knowledge. Safety is no different, and if we don’t expect electricians to know how to rewire a house solely by sitting in a classroom, then why would we expect anyone to be able to do the same for safety measures?

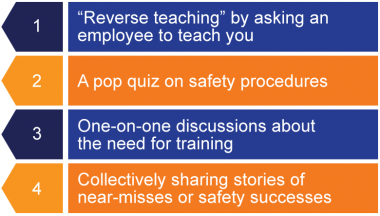

Hands-on training doesn’t have to mean looking over someone’s shoulder and then correcting them when they make a mistake. It could also include:

One technique I find particularly effective is to ask employees on the shop floor to rate their mental state or skill level. This evaluates not only how well they’re performing, but it also determines if they’re in a mental state (like rushing or complacency) that could cause them to circumvent safety procedures or put them at risk of making an error.

The aim is to elicit a trainee’s active participation in their own learning. By asking questions, their brains are forced to think through the problem and provide an answer—making them much more likely to remember it in the future.

There are significant financial and other incentives to strengthening safety performance at your company.

You’ll notice that many of these “hands-on” techniques don’t actually require you to be on the shop floor. The goal is to engage employees and not necessarily just observe them performing a task—you can use these methods in small groups or even incorporate them in classroom training.

You also have the opportunity to drastically shorten the feedback loop on incorrect behavior by immediately addressing any concerns rather than waiting until you observe it during the course of an employee’s work. And you can assess the extent to which an employee has learned the lesson in the first place and apply more pressure on topics that haven’t quite sunk in.

A helping hand

Of course, there can be challenges, too. For example, it can be administratively difficult to orchestrate and it may be difficult for safety supervisors to spend the necessary time with every employee. One way around this is to empower employees to do much of the heavy lifting for you. Try thinking of Health and Safety managers as the sheriff of a company’s safety. In many cases, you’re the lone officer in charge of policing a large population. But if you begin deputizing workers to do much of the policing on your behalf then you gain two major benefits.

The first benefit is that you will have more eyes looking out for safety issues, and with more observations being made there will be more safety improvement opportunities. The second is that your deputies are much less likely to break the safety laws that they’re helping to protect.

The first benefit is that you will have more eyes looking out for safety issues, and with more observations being made there will be more safety improvement opportunities. The second is that your deputies are much less likely to break the safety laws that they’re helping to protect.

The benefits of improving the effectiveness of your safety training by directly engaging employees is clear—a white paper published by the ASSP notes that there are significant financial and other incentives to strengthening safety performance at your company, and taking a direct and engagement-focused approach to safety training will do exactly that.

This is not to suggest that safety professionals should never deliver another classroom training session again. But providing a more regular mix of safety training that includes a strong hands-on component can help reinvigorate a safety program and allow safety trainers and supervisors to more effectively deliver safety lessons to employees.

Tim Page-Bottorff, CSP, CET is a senior SafeStart consultant, past president of the ASSP Arizona Chapter and a former United States Marine. As an OSHA trainer he is well-versed in how to facilitate effective training sessions and he frequently speaks about training and other safety topics at national safety conferences.

Get the PDF version

You can download a printable PDF of the article using the button below.