Givaudan is a global giant in the fragrance and flavor manufacturing business. With operations on six different continents, Givaudan employs nearly 10,000 workers. The company takes workplace safety extremely seriously. So when Givaudan noticed in 2009 that 26% of its total lost-time injuries occurred in Latin America, it was clear that something had to be done.

The real cause of Givaudan’s LTIs

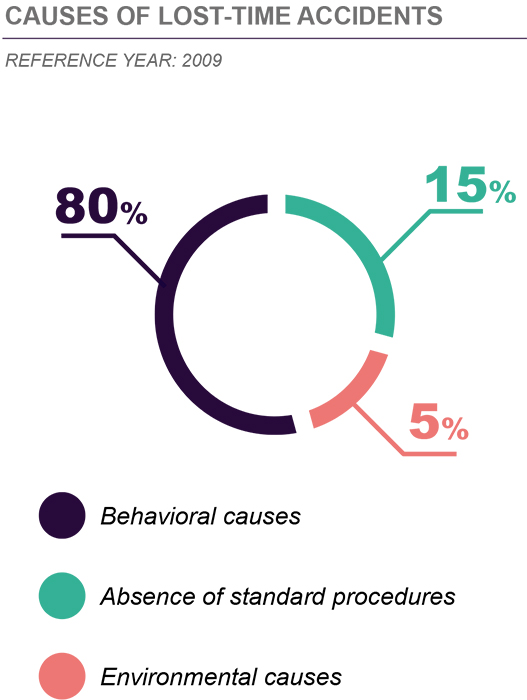

Givaudan’s EHS leaders spent a great deal of time and energy assessing their issues with employees getting hurt in the workplace. What they discovered is that 4 out of every 5 injuries were caused by employee behavior.

The executive team at Givaudan knew they needed to empower workers to make safer decisions. They also wanted a program that would inject life into the organization’s safety culture and that would mesh well with their other safety initiatives.

That’s why Givaudan turned to SafeStart.

Eye-popping reductions

Givaudan expects strong results from all its business partners. The company’s safety leaders were no different, and they were counting on SafeStart to provide a lasting injury reduction.

But no one expected the improvement to be quite so drastic.

After implementing SafeStart, Givaudan’s injuries dropped by 92% in Latin America. And the results had staying power—three years after completing the initial SafeStart implementation, injuries in Brazil were still 85% lower than the 2009 lost-time rate.

Learn more about Givaudan’s impressive safety achievements in this case study.

From their “Zero is Possible” safety program to discovering what the company’s EHS Director of Latin America says has “significantly reduced the number of lost-time accidents in the organization”, it’s well worth a read. Download the Givaudan case study here.