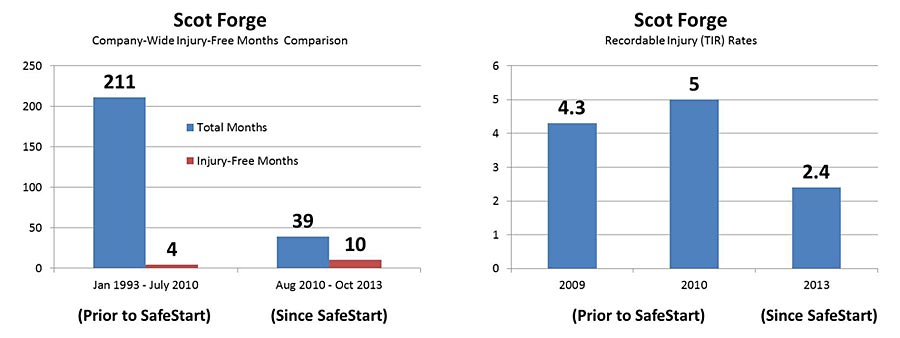

Since implementing SafeStart in 2010, Scot Forge has set several new safety records—their lowest number of recordable injuries ever, the most days without a recordable injury and the most company-wide injury-free months.

Scot Forge is a 100% employee-owned manufacturer of custom open die and rolled ring forgings. Started as a small hammer shop in Chicago, IL in 1893, the company has over 100 years of experience, leading the industry as one of the most modern and respected forging companies in the world. Operating with over 1,000,000 square feet of manufacturing space in five plants – over 250 million pounds of forgings is shipped from the company yearly.

John McGillivray, Manager, Safety & Environmental at the company reported, “Since implementing SafeStart in Aug 2010 and later adapting our BBS system to address the issues raised on the ACC cards in September 2012, our company has recorded 11 company-wide injury-free months in a span of 42 months. For the period of Jan 1993 through July 2010, a period of 211 months, going injury free as a company only occurred 3 times. We ended the year [2013] at our lowest number of recordable injuries ever as a company (18) which dropped our TIR to 2.4 (lowest ever). Our TIR’s for 2009 and 2010 were 4.3 and 5.0, respectively.”

Congratulations to John and the staff at Scot Forge and thank you for including SafeStart in your efforts to improve safety. We wish you continued success.

Contact us to learn how SafeStart compliments your existing programs to help you reach your corporate safety goals.