Hazard communication standards (HCS, also known as HazCom) exist to protect workers and the wider population from hazards such as flammable, carcinogenic, corrosive and poisonous materials. There are five main elements in HazCom: materials inventory, safety data sheets (SDS, formerly known as material safety data sheets or MSDS), labeling, written program and training. These elements are designed to provide workers with the information they need to handle various dangerous chemicals and materials safely.

In 2012, OSHA published a revision of the HazCom standard to align with the Globally Harmonized System for Classification and Labeling of Chemicals (GHS). GHS is a set of guidelines that defines and classifies hazards related to a chemical before communicating this information (and relevant protective measures) on labels and SDSs, which should be readily available to workers.

Each hazardous material needs its own detailed SDS that, according to OSHA, should contain 16 sections (4 of which are non-mandatory):

- Identification – Details of the chemical and its recommended uses, as well as the essential contact information of the supplier.

- Hazard(s) identification – Identification of the hazards related to the chemical and warning information associated with it. This needs to include, among other things, the hazard classification of the chemical including its category, a signal word, pictograms and precautionary statements.

- Composition/information on ingredients – Identification of the ingredients contained in the chemical, including impurities and stabilizing additives. This section should also contain information on substances (e.g., chemical name, common name and synonyms, and impurities) and mixtures. If any information pertaining to chemical identity and/or the concentration of chemicals is withheld as a trade secret, a statement confirming this is required.

- First-aid measures – First aid that should be given to a person exposed to the chemical, arranged by routes of exposure (e.g., inhalation, eye contact or ingestion). This should include a description of the most important symptoms or effects, including those that are acute or delayed.

- Fire-fighting measures – Recommendations for fighting a fire caused by the chemical, including suitable and unsuitable extinguishing equipment, as well as special protective equipment or precautions for firefighters. This section also contains information on hazards that develop in the fire (e.g., dangerous byproducts created when a chemical burns).

- Accidental release measures – Recommendations of the appropriate response in the event of spills, leaks, or releases. These can include containment (e.g., covering drains) and cleanup procedures (e.g., decontamination, neutralization or relevant equipment), as well as instructions for evacuation or protective clothing. This section can sometimes differentiate between large and small spills if the size of the spill can have an adverse effect on the hazard.

- Handling and storage – Safe handling practices and conditions for safe storage. Recommendations for specific safe storage requirements (e.g., temperature, humidity and ventilation), handling incompatible chemicals, minimizing the release of the chemical and general hygiene practices.

- Exposure controls/personal protection – Information on exposure limits (PELs, ACGIH, TLVs, etc.), engineering controls and personal protective measures (including any special requirements such as type of material used in the PPE) that can minimize worker exposure.

- Physical and chemical properties – Identification of physical and chemical properties of the substance or mixture. The minimum required information includes 18 properties, such as appearance, odor, upper and lower flammability or explosive limits, pH, melting point/freezing point, solubility, and auto-ignition temperature. Although not every one of the 18 items will be included in the SDS (due to relevance or availability of information), the reasons for their absence need to be noted. Other relevant properties not included in the basic 18 items can also be found in this section.

- Stability and reactivity – Information on reactivity hazards and chemical stability of the chemical divided into three parts: reactivity (e.g., class or family), chemical stability (e.g., stability under normal conditions, potential requirement for stabilizers, safety issues arising from the product changing its physical appearance), and other issues (e.g., possibility of hazardous reactions, conditions to be avoided such as vibrations, all classes of incompatible materials and anticipated decomposition products).

- Toxicological information – Information about toxicological and health effects or an indication that this info isn’t available). The information should include likely routes of exposure (e.g., inhalation, ingestion, skin and eye contact), effects from short- or long-term exposure (delayed, immediate, or chronic) and numerical measures of toxicity, symptoms (from the lowest to the most severe exposure). It should also indicate whether the chemical is listed in the latest edition of the NTP Report on Carcinogens, has been found to be a potential carcinogen in the latest IARC Monographs or found to be a potential carcinogen by OSHA.

- Ecological information (non-mandatory) – Information helpful to evaluating the environmental impact of the chemical if it were released into the environment. This could include data from toxicity tests on aquatic and/or terrestrial organisms, data on the potential for the chemical to persist and degrade in the environment, results of tests of bioaccumulation potential, the potential for groundwater contamination through the soil, and other adverse effects (e.g., ozone layer depletion potential and potential contribution to global warming).

- Disposal considerations (non-mandatory) – Guidance on proper disposal practices, recycling or reclamation of the chemical or its container, and safe handling practices with referrals to Section 8 (Exposure Controls/Personal Protection). This section could cover appropriate disposal containers, disposal methods, physical and chemical properties that may affect disposal activities, special precautions for landfills or incineration activities, and discouragement of sewage disposal.

- Transport information (non-mandatory) – Guidance on classification information for shipping and transportation of the chemical (by road, air, rail, or sea). This can include the UN number and proper shipping name, transport hazard class, or any special precautions to take in connection with transport or conveyance of the chemical.

- Regulatory information (non-mandatory) – Identification of the safety, health and environmental regulations specific for the product that are not indicated anywhere else on the SDS, such as national and/or regional regulatory information pertaining to the chemical or mixtures.

- Other information – Date of the SDS completion or last known revision, possible statement regarding the changes in the previous version, and any other relevant information.

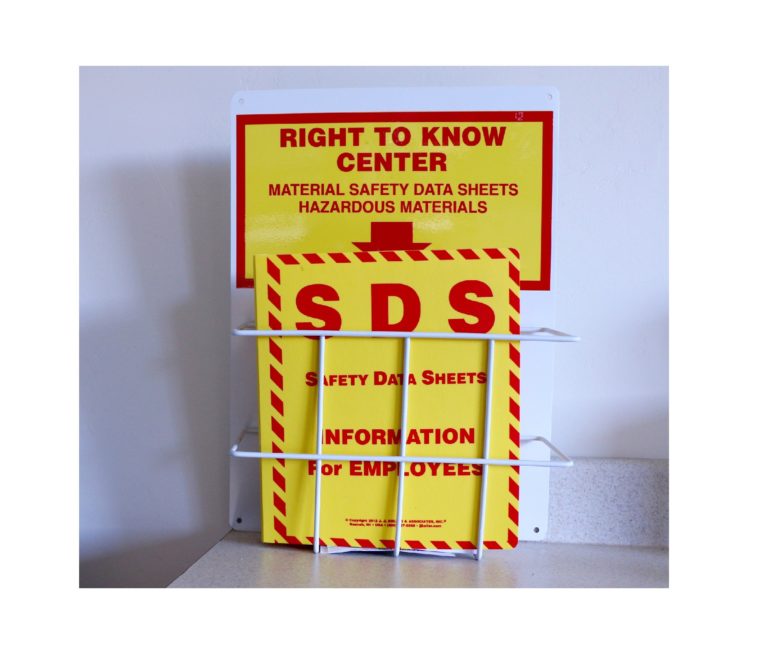

The “right-to-know” standard requires employers to provide workers with access to SDS, which allows them to know which chemicals they will encounter in the workplace and to understand how these chemicals may affect their health and safety. Every safety data sheet must be up-to-date, follow the above criteria and be easily available (especially in case of an emergency) for all hazardous materials present in your work area.